- TADCO ENGINEERING & ENVIRONMENTAL SERVICES

Non-Destructive Concrete Strength Testing

Non-destructive concrete strength testing is a method of investigating the compressive strength and other properties of concrete. As the term indicates, this approach is performed without damaging the concrete. Common strength properties of concrete include:

- Concrete hardness

- Resistivity

- Rebar location and orientation

- Concrete cover

- Rebar thickness

OUR SERVICES

Tadco’s Non-Destructive Concrete Testing Process:

Tadco’s trained professionals efficiently tackle the most sensitive non-destructive evaluation inspections. Architects, managers, and owners trust Tadco with resolving critical concrete concerns, especially regarding:

- Cracking

- Spauling

- Rust

- Exposure of rebar

- Strength of concrete

- Obtaining actual concrete strength in case of loading condition changes

By understanding specific needs, we can provide targeted exams of specific areas of concern. After coordinating a site visit to observe site conditions and areas of concern, we’ll build out a timely and actionable analysis report. Enclosed here are findings on referenced plans and in tabulated formats.

Tadco utilizes state of the art technology and equipment for maximum accuracy and precision in field data collection and production.

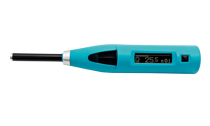

We most commonly use the SilverSchmidt, a unique integrated concrete test rebound hammer featuring true rebound value and thickness. The automatic calculation of rebound value is according to international standards. Its compact size and versatility allows use in tight spaces and hard-to-reach areas.

This device allows us to serve the professional architects and engineers in design and modifications of structures.

Additionally, we deploy the Profometer, which utilizes finely-tuned magnetic resonance detection. In conjunction with the patented Proceq computing device, this tool allows us to get concise mapping of rebar sizing, spacing and depth within existing concrete structures.

This technology allows results to be communicated in real-time. Its use is most beneficial in assessing large areas, and reports can be made available expeditiously.

For more precise results, we utilize Hilti X-Ray scanning technology, which zooms in very precisely to scan exact location, thickness and condition of the target area.

If you want to contact us about any issue please call (201) 610-9700

or send us an e-mail. If you would like to submit a proposal for consideration simply submit a quote.

KEEP UP TO DATE